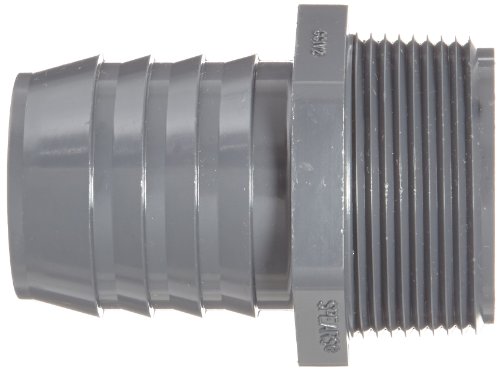

When it comes to plumbing projects, having reliable fittings is crucial to ensure a seamless connection and the longevity of the system. Today, we turn our attention to the Spears 1436 Series PVC Tube Fitting, an adapter that promises both durability and functionality for various piping needs. Crafted from sturdy gray polyvinyl chloride (PVC), this fitting features a male National Pipe Thread (NPT) on one end and a barbed insert on the other, allowing for easy attachment to ASTM schedule 40 polyethylene pipes.

Our experience with this particular fitting highlighted its impressive ability to create a secure seal when coupled with a hose clamp — an essential factor for preventing leaks in any plumbing system. Notably, it meets crucial standards, including ASTM D2609 for plastic insert fittings, ensuring it can withstand the demands of both residential and commercial applications. From its impressive maximum working temperature of 140 degrees Fahrenheit to its resistance against various chemicals, the Spears 1436 is designed for adaptability in a range of environments.

In this review, we’ll dive into our firsthand experiences with the Spears 1436 Series PVC Tube Fitting, exploring its performance in practical applications, ease of installation, and overall value. Join us as we unpack what makes this product a noteworthy contender in the realm of plumbing fittings.

Table of Contents

Overview of the Spears 1436 Series PVC Tube Fitting

The gray polyvinyl chloride (PVC) tube fitting we reviewed features a male National Pipe Thread (NPT) on one end, paired with a barbed insert designed specifically for a straight connection to ASTM schedule 40 polyethylene (PE) pipe. This design is particularly advantageous, as the barbed fitting allows for a secure attachment to flexible tubing when coupled with a hose clamp, ensuring a tight seal that is essential for fluid transfer. With its capability to withstand a maximum working temperature of up to 140 degrees Fahrenheit, this fitting is versatile enough to handle various applications. Additionally, its durability is highlighted by its resistance to a range of harmful substances, including acids, gasoline, alcohol, and hydrocarbons, making it a reliable choice for demanding environments.

In terms of standards and certifications, this tube fitting meets ASTM D2609 guidelines for plastic insert fittings and is NSF International 61 certified, confirming its safe use with potable water. Its thoughtful engineering focuses on both function and compliance, giving us peace of mind when incorporating it into our projects. Furthermore, the product dimensions reveal a lightweight design, weighing only 1.76 ounces, which adds to its practicality without compromising strength. As we seek to connect various plumbing components, we find this fitting not only meets our needs but also aligns with the expected quality standards set by Spears Manufacturing since its establishment in 1969.

Diving into the Features of the Adapter

The adapter boasts several standout features that cater to both versatility and durability in various plumbing applications. Made from gray polyvinyl chloride (PVC) plastic, it connects seamlessly to ASTM schedule 40 polyethylene (PE) pipes, ensuring a robust and long-lasting performance. One end features a male National Pipe Thread (NPT) for direct connection, while the other sports a barbed insert that guarantees a tight fit. For enhanced security, utilizing a hose clamp (sold separately) with the barbed fitting can prevent leaks and ensure a seamless flow of fluids.

Furthermore, this product is engineered to withstand a maximum working temperature of 140 degrees Fahrenheit and is resistant to reactions with various substances, including acids, gasoline, alcohol, and hydrocarbons. Its design meets ASTM D2609 standards for plastic insert fittings, making it a reliable choice for potable water applications, as it is also NSF International 61 certified. When selecting pipe fittings, it’s essential to consider the specific requirements of your project, and this adapter uniquely combines functionality with high-performance standards.

| Feature | Specification |

|---|---|

| Material | PVC |

| Temperature Resistance | 140°F (60°C) |

| Certification | NSF 61 for Potable Water |

| Connection Type | Barbed & NPT Male |

Our Insights on Performance and Versatility

Our Insights on Performance and Versatility

We found that this fitting excels in both performance and versatility, making it a reliable choice for a variety of applications. Its construction from durable gray polyvinyl chloride (PVC) not only ensures strength but also provides excellent resistance to a range of chemical reactions, including acids and gasoline. With a maximum working temperature of 140 degrees Fahrenheit, it performs well in environments where heat may be a factor, while maintaining a secure connection thanks to the barbed insert design. This feature, when combined with a hose clamp (sold separately), facilitates a tight seal on flexible polyethylene pipe, effectively reducing leakage risks.

Moreover, this product meets stringent industry standards such as ASTM D2609 for plastic insert fittings and NSF 61 for potable water use. This certification allows us to use it confidently in various systems, including plumbing and drainage setups, where safety is paramount. The straightforward barbed-to-NPT connection also simplifies installation, catering to both DIY enthusiasts and professionals alike. In our experience, this fitting has proven its capabilities in both domestic and industrial settings, making it an adaptable solution that can easily transition between different tasks. For a closer look at this versatile fitting, check it out here.

Recommendations for Optimal Use and Maintenance

To ensure the best performance of our PVC tube fitting, we recommend pairing it with a suitable hose clamp to create a tight seal around the flexible polyethylene pipe. This step is crucial as it enhances the connection integrity during operation, preventing leaks and ensuring maximum durability. Additionally, when installing the fitting, we should ensure that it is aligned properly to avoid unnecessary stress on the joints, which can lead to premature wear or failure. It is also important to consider the working temperature; our fitting can handle up to 140 degrees F, so we should avoid using it in environments that exceed this limit.

Maintaining our fitting involves routine inspections for any signs of wear, corrosion, or damage, particularly around the barbed and threaded sections. If we find any irregularities, it’s best to replace the fitting to avoid system failures. Regular cleaning is also vital—using compatible cleaning agents to remove any debris or contaminants can significantly extend the life of the fitting. Lastly, we want to make sure to store the fitting in a dry place, away from direct sunlight and harsh chemicals, to preserve its integrity. By following these recommendations, we can optimize the performance and longevity of our fitting.

Customer Reviews Analysis

Customer Reviews Analysis

When delving into the user experiences surrounding the Spears 1436 Series PVC Tube Fitting, we find a tapestry of feedback that underscores both the effectiveness and the versatility of this product. From dishwasher drain installations to garden hose replacements, our customers have shared their insights and anecdotes that illuminate the true value of this fitting.

| Review Summary | Key Points |

|---|---|

| Reliable and Leak-Proof | Many users reported zero leaks and strong hold when installed. |

| Ease of Installation | A majority found it straightforward to install, despite some needing tools for a snug fit. |

| Durable and Long-Lasting | Customers praised the product’s sturdiness, even under frequent use. |

| Cost vs. Value | Some considered it more expensive than store brands, but valued the quality and convenience of delivery. |

From one practical application to another, our reviews highlight common themes. A satisfied customer mentioned using the fitting to replace a corroded metal end, noting, “These are very sturdy and reliable.” This sentiment resonates with several users who particularly emphasized the robustness of its construction. It’s worth considering that while some fittings might offer a lower price tag, they lack the lasting power and effectiveness that the Spears 1436 provides.

The product has also been lauded for its versatility. One user shared their experience connecting the fitting to a pond filter, effectively transforming a simple plumbing product into a multifaceted tool for different environments. Its compatibility with various setups seems to make it an indispensable piece in a DIY toolkit.

Commonly, users shared thoughts about their installation processes. Many found the installation manageable, and those who encountered difficulty also noted it was more a matter of technique than a flaw in the product. For instance, a user mentioning the need for a mallet to secure the fitting into their hose shows that while it may require a bit of effort, the end result is worth it.

we recognize the Spears 1436 Series PVC Tube Fitting as a highly rated choice among our customers, particularly for those seeking reliability and durability in their plumbing projects. Whether it’s for simple home repairs or more elaborate water management tasks, the feedback we’ve gathered confirms that this fitting lives up to its promise.

Pros & Cons

Pros & Cons

As we explore the versatility of the Spears 1436 Series PVC Tube Fitting, it becomes essential to summarize the strengths and weaknesses of this product. Below is a comprehensive list that highlights what we believe to be the most relevant aspects of this adapter.

| Pros | Cons |

|---|---|

| Durable Material: Made of high-quality PVC, the fitting is resistant to reactions with various chemicals, including acids and gasoline. | Temperature Limitation: The maximum working temperature of 140°F may restrict use in high-heat applications. |

| Tight Seal: The barbed design ensures a secure fit with flexible PE pipe when paired with a hose clamp. | Extra Accessories Needed: A hose clamp is required for complete installation, which isn’t included in the package. |

| Industry Standards: Meets ASTM D2609 and NSF 61 certifications, ensuring safety and reliability for potable water applications. | Limited Size Options: The product is available in a single size, which may not suit all project requirements. |

| Versatile Applications: Suitable for various applications, including fluid transfer and waste management. | Installation Complexity: Proper installation may require some plumbing knowledge for optimal results. |

Ultimately, the Spears 1436 Series PVC Tube Fitting offers a blend of durability and functionality suitable for a wide range of uses. However, users should be mindful of the temperature limitations and the need for additional components during installation.

Q&A

Q&A Section

Q1: What materials is the Spears 1436 PVC Tube Fitting made from?

A1: The Spears 1436 PVC Tube Fitting is crafted from gray polyvinyl chloride (PVC) plastic. This material is known for its strength and resistance to a variety of chemicals, making it ideal for use in various fluid systems.

Q2: What are the specific applications for this tube fitting?

A2: This fitting is designed for connecting a male National Pipe Thread (NPT) pipe to an ASTM International schedule 40 polyethylene (PE) flexible tubing in a straight run. It’s commonly used in plumbing, irrigation, and various industrial applications where reliable fluid conveyance is necessary.

Q3: Is this fitting suitable for potable water use?

A3: Yes, it is NSF International 61 certified, which means it meets safety standards for use with drinking water. This makes the Spears 1436 fitting a safe choice for potable water applications, provided it is installed correctly.

Q4: What is the maximum working temperature and pressure for this fitting?

A4: The maximum working temperature for the Spears 1436 fitting is 140 degrees Fahrenheit. The pressure rating is dependent on the specifications of the PE tubing being used; thus, it’s essential to check the tubing’s rating to ensure compatibility.

Q5: Do we need any additional components for installation?

A5: Yes, to secure the barbed end of the fitting to the flexible PE tubing, a hose clamp is required (sold separately). This clamp creates a tight seal, preventing leaks at the connection point.

Q6: How does this fitting handle chemical exposure?

A6: One of the advantages of the PVC material used in the Spears fitting is its inherent resistance to various chemicals, including acids, gasoline, alcohol, and hydrocarbons. This makes it a versatile choice for applications that involve exposure to such substances.

Q7: Are there any specific standards that this fitting meets?

A7: Certainly! The Spears 1436 series fitting complies with ASTM D2609 standards for plastic insert fittings and is also compliant with ASTM schedule 40 standards for wall thickness. This means it’s built to withstand the rigors of commercial and industrial use.

Q8: Can we expect long-term durability from this fitting?

A8: Yes, the Spears 1436 PVC Tube Fitting is designed for durability and longevity. Its robust construction and chemical resistance ensure that it can perform effectively in demanding environments, making it a reliable choice for a variety of applications.

Q9: What are the fitting’s dimensions and weight?

A9: The product dimensions are 8 x 8 x 5 inches, and it weighs approximately 1.76 ounces. Its compact size makes it easy to handle and install in various settings without taking up much space.

Q10: Where can we purchase the Spears 1436 Tube Fitting?

A10: The Spears 1436 PVC Tube Fitting can typically be found through plumbing supply stores, home improvement retailers, or various online marketplaces. Just be sure to confirm that you’re purchasing from a reputable source for quality assurance.

Feel free to explore further if you have more questions or need guidance on getting the most from your Spears 1436 PVC Tube Fitting!

Transform Your World

As we wrap up our exploration of the versatility of the Spears 1436 Series PVC Tube Fitting, it’s clear that this adapter is designed with practicality and ease of use in mind. Its ability to create a secure seal, compatibility with diverse piping applications, and robust chemical resistance make it a worthy addition to any toolkit. Whether we’re tackling projects involving potable water systems or industrial applications, the reliable performance of this fitting ensures that our connections are strong and safe.

In the world of pipe fittings, choosing the right component can make all the difference, and we believe the Spears 1436 adapter stands out as a dependable choice for both professionals and DIY enthusiasts alike. So, if you’re looking to enhance your plumbing projects or simply want a reliable solution for connecting polyethylene tubing, we highly recommend considering this fitting.

Ready to take the next step in your projects? Discover more about the Spears 1436 Series PVC Tube Fitting and make it part of your toolkit by visiting the link below!